Long Term Label Project

A Long Term Label Project With a Happy Ending.

We never know who is on the other end of the line the first time we answer a call requesting help. Some projects are simple bar code tracking labels that we have been making since the early 1980’s, and then there are the projects that creep along for years.

About 4 years ago we received a call about a label needed for a military grade application. After numerous rounds of testing and re-configuring, the label has finally been approved. The point is that sometimes getting the right label for the job is more important than throwing something out there and hoping is sticks (pun intended).

We pride ourselves on our quick response, but more importantly, we pride ourselves on helping our customer identify environmental conditions that affect the label’s performance and helping find a resolution.

Tips for creating the perfect label:

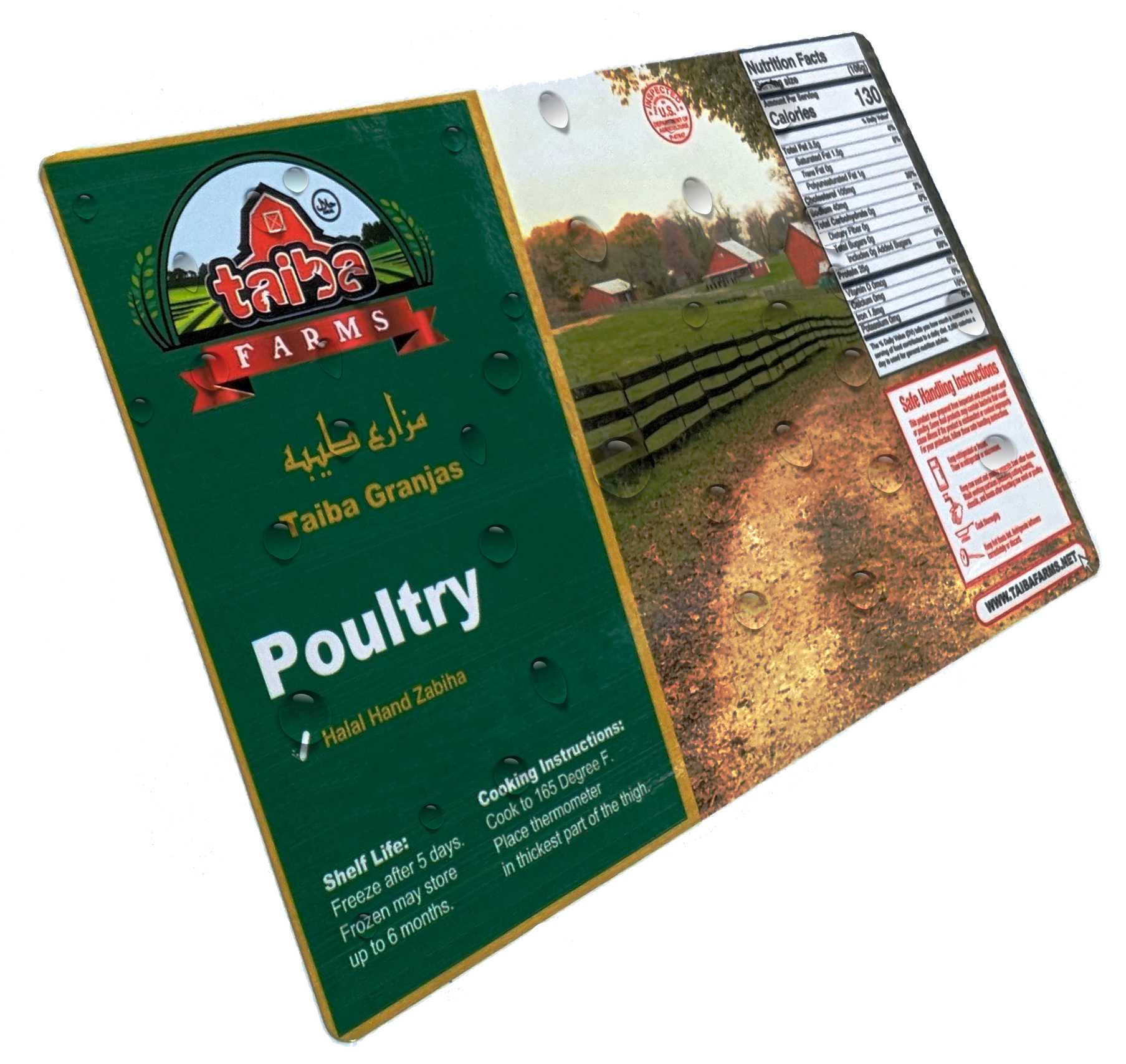

- How is your label used? Is the label intended for a short life food product or does the label need to identify a product that could be in service for many years, like automotive labels?

- What is the surface of your product like? Is it flat or is it deeply textured?

- What is the temperature range of your product and very importantly what will the temperature of your product be at the time the label is attached? Adhesives can work at very low temperatures but must be applied at a temperature well above freezing.

- How durable does the print need to be?

- Will the print be exposed to grease or chemicals?

- Will the print be exposed to direct sun and rain?

- Very few label designs take 4 years to be developed and tested. In the case of the military application, testing was key in making sure we got it right and that all the pieces were in place.

As it turns out, our customer was so happy with the final label design that they invited me to visit them at the Pentagon and gave me a private two hour tour.