Why use Polyester over Vinyl or Vinyl over Polypropylene for labels?

How do you decide what is the correct label material for a label project?

Polypropylene, Polyester and Vinyl are the most common materials used to make labels (when choosing from plastic based materials) and I have been asked these questions many times over the years and for which the answer usually is “It depends”.

Choosing label material is a function of how the labels will be used and what environment they will be subject to.

At times materials can be interchanged with no ill effects. If the item to be labeled has a very short shelf life and the quantity needed is low, the biggest determining factors are what material is available, cost and what looks the best off the printing press that has the shortest setup time.

Other times the material is so critical that lives are dependent on having a readable label 10 years from the day the label was applied. When car parts are recalled a label may be the only way to track the part back to the manufacturer, when the part was made, and what other cars have installed the part from the same faulty batch. If the tracking number is unreadable the manufacturer would have to recall not only the vehicles with the bad batch of parts but every vehicle that the part was ever installed.

Where do I start when deciding on label material?

It helps to understand some of the pros and cons of each material and to evaluate them against your project’s requirements. Our expertise has evolved around industrial, governmental and logistics labeling so a majority of the material we work with is Polyester. Our equipment is “roll to roll” which means we do not use cut flat sheets like a screen or offset printer might use which influences the material selection available to us.

The type of printing used to make the labels plays a part in in the decision process. I will leave that for a future discussion except to say that when there is not much difference in the performance between one material over another, the printer is likely to steer the end user toward the material that they are most comfortable with.

As I go through the PROS and CONS I will add links to material data sheets to demonstrate specific properties whenever possible.

Polyester Labels

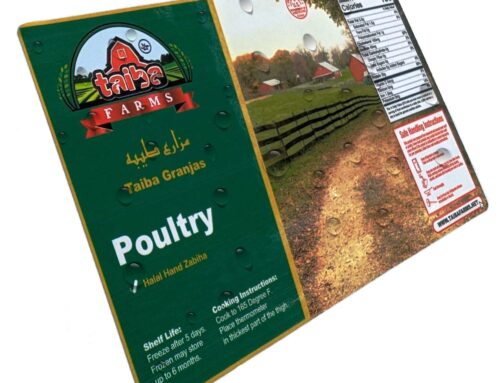

Also known as PET (polyethylene terephthalate) and Mylar. Polyester is light weight, semi-rigid with excellent moisture barrier properties and comes in a wide range of adhesives. A great material when durability and a long life matters.

Pros of Using Polyester Labels:

- Life-Span – Labels can last many years (10 years plus in some cases). Although most material manufacturers will not guarantee their materials longer than one or two years to their converters; we tested durability by applying labels to outdoor steel fencing and depending on the material some labels lasted over 10 years.

- High Temp – Up to 300° F for short periods of time. (3M 7871)

- Low Temp – Usually bottom out at around -40° F. (3M 7879) Adhesive plays a big part in the actual application temperature. Most cryogenic labels (-320° F) are made with Polypropylene.

- Thickness – Thin, normally between 2 and 2.5mil.

- Clarity – Very clear but not considered as clear as some Polypropylene. (Fasson 79325)

- Outdoor Stability – UV stabilizers can be added for additional protection from the sun exposure. (Flexcon FLX027651)

- Chemical Resistance – Polyesters can stand up some of the most caustic and acidic chemicals. (Link to Resistance Chart)

- Metalized – Polyesters can come in matte or bright silver. (Spinnaker 41779)

Printing Surface – Very flat and even for fine high-quality printing. Most Polyesters are coated to receive resin thermal transfer print which is the most durable and scuff resistant type of thermal transfer printing available. (Flexcon FLX000318) - Moisture Resistance – Offers excellent resistance to water.

Cons of Using Polyester Labels

- Stiffness – Polyesters are not very conformable. They should not be used on irregular surfaces or on containers with small circumference which can end up in flagging; the edge of the label wants to peel back.

- Flexibility – Not good for squeezable packaging because it tends to pucker at the edges.

- Expense – Polyester is generally the most expensive of the three label materials.

Polypropylene Labels

Generally referred to as Polypro, PP or BOPP (Biaxially Oriented Polypropylene) is great low-cost moisture resistant film best used for items with a short life span. Good for short lived products that need moisture resistance such as food packaging.

Pros of Using Polypropylene Labels:

- Cost – Very economical for a water-resistant durable label.

Water Resistant Polypropylene

- Clarity – Ultra-clear Polypropylene when paired with a clear polyester liner helps keep the adhesive side smooth to remove any irregular surface marks that you could get from a kraft liner. (Fasson 75386)

- Low Temp – Some cryogenic polypropylene can reach to -320° F. (Fasson 79802)

- Moisture Resistance – Offers excellent resistance to water.

- Printing Surface – Very smooth for printing fine high-quality images via Flexographic and Thermal Transfer.

- Stiffness – Polypropylene is fairly flexible and is less likely to flag when applied to a small circumference container. This makes it a natural choice for small bottles, test tubes and ampules. (Fasson 76910)

- Recyclability – Of the three materials, Polypropylene is probably the most easily recycled but only if the object that the label is affixed to is also Polypropylene.

Cons of Using Polypropylene Labels:

- Life-Span – Most Polypropylene has a maximum life of around 18 months which can be extended by keeping the labels away from exposure to sun light.

- Digital Printing – Depending on the coating and make-up of the Polypropylene, the material can leave streaks. Matte Polypropylene (Spinnaker 41912) seems to work best in solving this issue which can always be laminated if a gloss look is desired.

- Scuff Resistance – When printing via a thermal transfer printer most Polypropylene will only accept a Wax/Resin ribbon which will give only moderate scuff resistance.

- High Temp – Lower temperature range (150° – 200° F) when compared to Polyester and Vinyl.

- Chemical Resistance – The least chemical resistant of the three materials. (Link to Resistance Chart)

Vinyl Labels

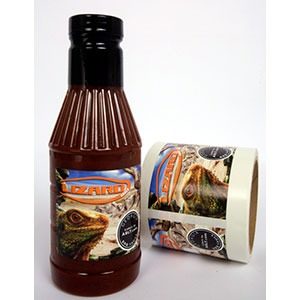

Also known as PVC (Polyvinyl Chloride) is used in its flexible form for labels because of its ability to conform and for its durability. Vinyl is a good middle of the road material when need for durability and price sensitivity meet.

Pros of Using Vinyl Labels:

- Cost – Low-end Vinyl is somewhat less expensive then low-end Polyesters while high-end Vinyl is a lot less expensive then high-end Polyesters.

Outdoor Vinyl

- Flexibility – Or conformability, Vinyl is very good for irregular shaped objects because of its lack of memory (think wet noodle).

- Life-Span – Fairly long outdoor life of around 5 years depending on the formulation of the Vinyl.

- Outdoor Stability – Has good protection from UV exposure but could yellow over time if not protected by a UV resistant coating or film.

- High Temp – Some special Vinyl can reach up to 300° F (3M OFV0202) for short periods of time but most top out around 275° F.

- Abrasion Resistant – The material has great abrasion resistance but must be married with the correct ink or laminate to ensure scuff resistance to print.

- Moisture Resistance – Offers excellent resistance to water.

- Chemical Resistance – Vinyl can stand up many caustic and acidic chemicals. (Link to Chemical Resistance Chart)

Cons of Using Vinyl Labels:

- Thickness – Vinyl thickness usually starts at 3.5mil and can range up to 8mil. Sometimes having a thicker label can be considered a positive property but more material usually means more expense for both the material and shipping costs.

- Printing Surface – Not advisable for fine printing such as high-density barcodes.

- Thermal Transfer Print – Does not print well with Resin ribbons. Additionally, Vinyl can even be finicky with Wax/Resin ribbons.

- Clarity – Not good for ultra-clear projects.

Label Materials Comparison Table:

| Property | Polyester | Vinyl | Polypropylene |

|---|---|---|---|

| Life Span | Excellent | Good/Excellent | Poor |

| High Temp | Excellent | Good | Good/Poor |

| Low Temp | Good | Good | Excellent |

| Thickness | Thin | Thick | Thin |

| Outdoor Stability | Excellent | Good | Poor |

| Chemical Resistance | Excellent | Excellent | Good |

| Clarity | Excellent | Poor | Excellent |

| Printing Surface | Excellent | Good | Good |

| Moisture Resistance | Excellent | Excellent | Excellent |

| Conformability | Poor | Excellent | Good |

| Cost | High | Medium | Low |

| Thermal Transfer Printing | Excellent | Good but could smudge | Excellent but could smudge |

How do I tell what label material I have?

If you have a label now that is working for you but don’t know what the material is there are a couple of easy tests.

First test – See if it is Vinyl

Vinyl is the easiest because it is flexible, stretches and is normally thicker than Polyester and Polypropylene. Additionally, it has a plastic smell like a new shower curtain.

Next – Is it Polypropylene or Polyester?

If it is not Vinyl, then it is probably a Polypropylene or Polyester. The test to determine which it is, is easy

The hardest part of this test is that you must remove all the adhesive from the label first. This can take some time but by rubbing the back of the label with Goo Gone you can easily remove the adhesive. Make sure all adhesive is off before testing the material or you may get a false result.

Once the adhesive is removed put each material in a glass of water and if the label floats it is a polypropylene.

Each of these materials has a wide range of characteristics that can influence the end result!

I hope now you have a better idea of some of the properties needed to judge how well these materials perform in various situations.

Call Us

If you have a label project that you need help with, please contact us and we would be happy to advise. Advanced Barcode & Label Technologies, Inc. has been in business since 1984 and has a proven history of partnering with clients to solve their complex label needs.

Need a quote? Have questions about choosing a label material?

Talk to a label expert at 800-321-3653 or 404-671-3150

Or submit your specifications HERE